years on logistics IT solutions

years on logistics IT solutions

integrations with other systems including manufacturing, distribution, ERP systems.

Inland Depot & marine terminals under service

logistics companies work in this application

Increase in revenue due to all processes optimization — maximizing your return on investment

of supply chains types of cargo with central management

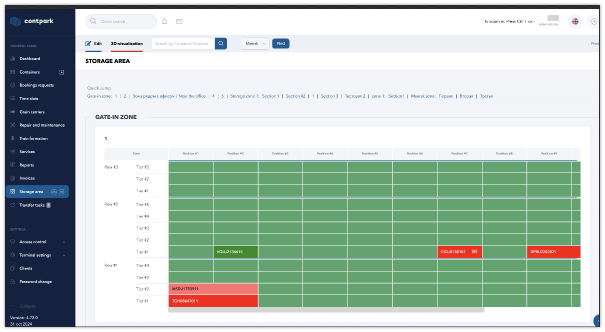

Intermodal software sorts containers/ tanks into groups and filters them by required parameters in real time. It allows for easy transfer from gate-in to gate-out. The interface is user-friendly. It also allows for convenient import / export of data in Excel.

The solution provides full transport control by recording arrivals / departures, transport types, drivers info without special handling. Additionally, the time-slot feature can be used to create priorities. Our solution provides an effective yard management system, including a record of gate in/out terminal operations, drivers and trucks registry.

Terminal Operating System (TOS) play a crucial role in supply chain management by providing end-to-end visibility and control over the flow of goods and information. TOS enables efficient planning and execution of transportation and logistics operations, including truck, rail, and vessel scheduling. It also supports optimization of carrier resources and facilitates seamless coordination between different parties involved in the supply chain.

Another important capability of Terminal Operating System (TOS) is their integration with Yard Management Systems (YMS). This integration enables real-time monitoring and control of yard activities, such as container storage, movement, and retrieval. The TOS-YMS integration allows for optimized yard utilization, improves operational efficiency, and reduces dwell times for containers.

Grain warehouses’ effective solution. Record of arrival/departure operations, drivers’ , trucks’ registry, and more.

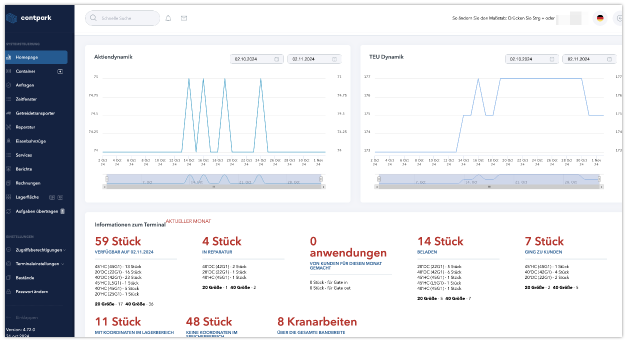

Our advanced statistics generate reports for any selected time period, segmented by customer. The terminal operating system properly, creating reports in a click. Personal customer accounts provide important info about carriers quickly.

We also provide a guide for vehicles, products, equipment, with a personal app account for each authority to optimize the entire customs clearance process. The data for cargo is transferred in real time via the EDI (Codeco) international protocol.

Our Record of Reception and General Cargo Dispatch solution, Cont Park apps, includes a DGPS system for general burden transshipment, such as bulk, propelled, project cargo.

Terminal Operating System (TOS) provide comprehensive solutions for managing port and terminal operations. This includes planning and scheduling vessel berthing, optimizing crane utilization, coordinating container exchanges, and managing traffic within the terminal. TOS enables efficient control and coordination of port activities, enhances operational productivity, and ensures smooth flow of cargo through the terminal.

Our Container Condition Control feature allows the creator of a repair statement to print a condition statement. In the personal account of the software owner, they can see data about every defect in equipment, accept or decline a repair.

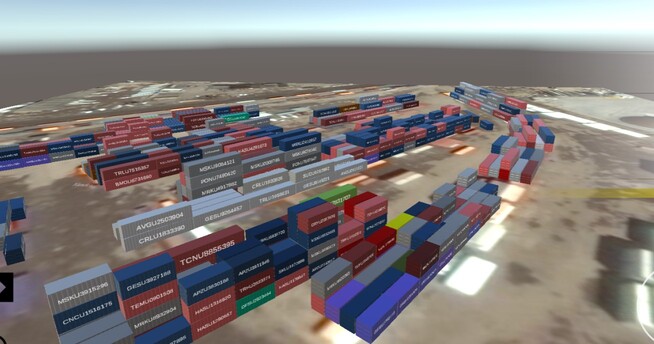

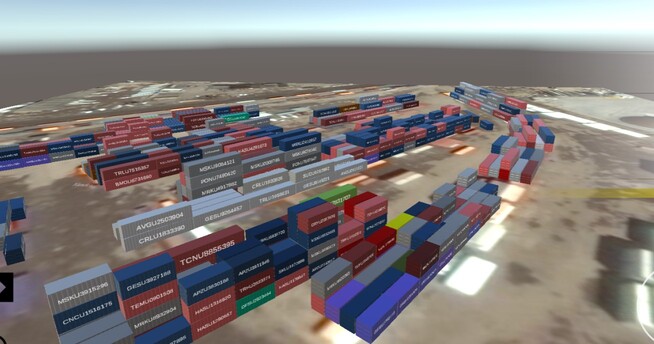

Operators can view all actions with a particular in real-time, record its movements and yard history. Our intelligent programmatic solution creates movement reports relocates units on a 2D map of the terminal via portable devices.

A key feature of Terminal Operating System (TOS) is their integration with Warehouse Management Systems (WMS). This allows for efficient management and control of warehouse operations, including inventory tracking, order processing, and fulfillment. The TOS-WMS integration enables real-time visibility of stock levels, facilitates accurate stock replenishment, and supports efficient picking and packing processes.

Terminal Operating System (TOS) offer features and capabilities for managing equipment maintenance. This includes the tracking of maintenance records, scheduling preventive maintenance tasks, and initiating maintenance and repair work orders. By efficiently managing equipment maintenance, TOS helps to ensure optimal equipment performance, minimize downtime, and improve overall operational efficiency.

A terminal operating system (TOS) is a computer software system that manages and controls the operations of a container terminal. It is responsible for coordinating all the activities that take place in a terminal, from the incoming and outgoing cargo to the handling of equipment and personnel.

A TOS works by centralizing all the information needed to operate a terminal, such as container location, vessel schedules and yard plans. It then uses this data to optimize the terminal’s operations, streamline the flow of cargo and minimize waiting time for vessels, trucks and other equipment.

There are multiple benefits to using a TOS, including:

• Increased terminal efficiency, productivity

• Improved inventory control, accuracy

• Better visibility, tracking of container movements

• Enhanced safety, security measures

• Improved communication among all terminal stakeholders

1. Streamlined process flow

2. Increased efficiency, productivity

3. Improved accuracy, reliability

4. Real-time data, visibility

5. Better inventory management

6. Enhanced customer service

7. Cost savings, reduced operational expenses

A cloud container terminal operating system is a software platform that operates on the cloud, designed to manage container terminal operations. It consists of various modules that provide terminal operators with tools to manage their operations, including vessel, yard, quay, gate functions, among others. The system allows for real-time tracking, inventory management, revenue management, automated workflow management. It enables terminal operators to optimize operational efficiencies, reduce terminal congestion, improve throughput, productivity. Additionally, the cloud-based system offers scalability, cost-effectiveness, high accessibility—making it suitable for modern terminal operations.

It was sent successfully.