Welcome to Contpark – The Future of Container Terminal Management

Contpark revolutionizes truck and rail terminal operations worldwide, serving as a leading container terminal and logistics management software system. It offers precise real-time container tracking, improving handling, stowage planning, and cargo flow optimization. Leveraging advanced technology and automation integrated with analytics, Contpark boosts productivity and streamlines operations, ensuring effective container management across terminals.

At the core of Contpark’s innovation lie its primary benefits: automation of operations to diminish errors, delivery of strategic insights for ongoing process enhancement, and significant cost savings. These benefits are crucial in improving terminal operations, maximizing equipment utilization, and ensuring effective container and traffic management.

Key Features of Contpark:

- Operational Efficiency: Leveraging Intelligent Planning and Space Optimization, Contpark guarantees peak operational performance.

- Data Accuracy: Ensures exact traffic management and container allocation, lowering error chances.

- Optimization: Contpark enables terminals to optimize equipment use and reduce downtime, facilitating smoother operations.

Adopting Contpark signifies a leap towards operational superiority and substantial cost efficiency, positioning truck and rail container terminals for success in a vibrant industry environment.

Features operating system:

- Empty/loaded, tanks, trailers, vehicles, trucks

- Type/size

- Terminal handling

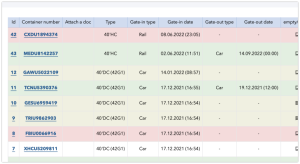

- Gate-in/out

- Real-time transportation’s visibility products for business

- Vehicles parking time-slot

- Accounting for orders and arrivals

- Manage a reach stackers’ transfer, other employees on a tablet

- Tasks for lifting equipment, performance monitoring

- Movements’ analytics by customers’ stocks

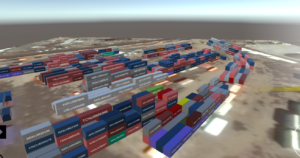

- Yard visualization, implementation

- Warehouse constructor platform

- Location of rows and tiers

- 2D/3D virtual yard map

- Detailed reports’ generation for customer service, sending messages and alerts

- export doc/xls/pdf

- Dock activities’ development/maintenance

- Improved loads’ monitoring/auditing

- Save time/money

- Increase productivity

- Shipments’s prioritizing

- Personal accounts for staff, customers

- Roll settings

- Owner account

- Fulfill a monitoring’s needs/requirements

- Container movement optimization

- Windows

- Linux

- MacOS

- Android

- iOS

- Every week

- Online data exchange via EDI / API with Shipping Lines

- Monitoring of reach stackers and crane

- Translation into popular world languages

- Accounting for all changes on the terminal

- Visual damage editor service

- Acceptance/refusal of repair

- Operation notifications

- Chat with clients

- Support for customer

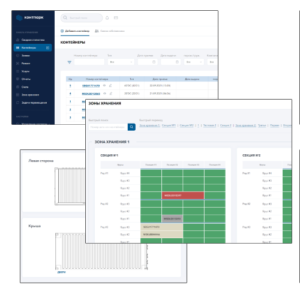

Interface:

Maintenance and mend. Acceptance or refusal to fixing in a client's personal account.

Maintenance and mend. Acceptance or refusal to fixing in a client's personal account.

Convenient stacking function with visible in-plane display.

Convenient stacking function with visible in-plane display.

Terminal design editor. Stack modeling and container search functionality.

Terminal design editor. Stack modeling and container search functionality.

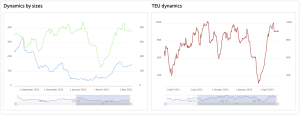

Analytical information on clients and financial parameters.

Analytical information on clients and financial parameters.

Usability on mobile devices. Android, Ios, Windows, Imac, Linux

Usability on mobile devices. Android, Ios, Windows, Imac, Linux

Complex Billing. Automatic generation of invoices.

Complex Billing. Automatic generation of invoices.

|

Freeware demo – 14 days |  |

Download presentation / brochure (PDF) |

FAQ

A Container Terminal Management System is a sophisticated tool designed to automate and refine operations at container terminals. It focuses on streamlining container movements, storage, and tracking with digital efficiency. Utilizing advanced technology, the system increases efficiency, reduces mistakes, and elevates productivity.

A Container Terminal Management System includes:

Container Tracking and Visibility: Provides instant tracking, enabling precise monitoring of container locations and statuses.

Yard Planning: Manages container storage, overseeing allocation, stacking, and retrieval.

Gate Operations: Enhances truck flow at Gate in/out points, streamlines processes, reduces turnaround times.

Vessel and Berth Planning: Aids in scheduling vessel movements, optimizing space and capacity.

Crane and Equipment Handling: Allocates cranes and equipment, boosts resource efficiency, minimizes downtime.

Inventory Control: Tracks container types, quantities, movements, ensuring effective management.

Reporting and Analytics: Delivers reports and analytics for operational insights, performance, trends.

Integration with External Systems: Facilitates data flow with external platforms (customs, billing), automating processes.

Implementing a Container Terminal Management System yields numerous advantages:

- Boosted Efficiency and Productivity: Enhances operations through automation and optimization, leading to higher productivity.

- Improved Tracking and Visibility: Offers real-time container tracking, ensuring timely planning and coordination, and better customer service.

- Reduced Errors and Data Duplication: Cuts down manual data entry errors and eliminates duplicate data through automation.

- Efficient Gate Operations: Streamlines gate processes, decreasing truck wait times, enhancing throughput, and expanding capacity.

- Optimal Yard Management: Ensures efficient use of yard space and container stacking, minimizing unnecessary movement.

- Real-time Monitoring and Reporting: Facilitates immediate decision-making with up-to-date monitoring and reporting.

- Enhanced Resource and Equipment Planning: Provides insights for better resource and equipment management, reducing idle times.

- Seamless External Integration: Improves data exchange with external systems, enhancing coordination and reducing manual tasks.

Yes, many systems are built to oversee multiple locations. They offer centralized management and visibility, enabling operators to effectively control and oversee operations across various sites.

The implementation timeline for a Container Terminal Management System can vary depending on factors such as the complexity of container terminal operations, size, and customization requirements. Generally, a full-scale implementation can take several months to a year, encompassing platform configuration, data migration, testing, and training.

Yes, training is typically provided by the vendor or implementation team. User training familiarizes staff with the functionalities, while administrator training is offered to those responsible for managing and configuring.

Yes, are designed to integrate with others to facilitate seamless information exchange. This includes integration with customs, billing, shipping line, port community systems, and other logistics and supply chain solutions.

Yes, are designed with scalability in mind. They can accommodate the growth and changing needs, including increasing their volumes, additional terminals or locations, and the incorporation of new functionalities or modules as required.

Vendors typically provide technical support and maintenance services. This includes troubleshooting assistance, application updates, bug fixes, and general maintenance to ensure smooth and uninterrupted processes.

Can often be customized to meet the specific requirements. Customization may involve configuring workflows, data fields, reports, and user roles to align with the unique operational needs. Additional development or consulting services from the vendor may be required for such customizations.

Case - integration of Container terminal management system

| TYPE | Container depot. Reception / delivery: AUTO |

| Storage capacity | 1200-2400 TEU |

| Warehouse | Empty, loaded, refrigerators, box, vehicles |

| Services | Storing empty, laden, filling, unloading |

| Region | China, Shenzhen |

| Departments | Reception/dispatch, fixing team, accounting, storage / warehousing |

Solutions applied:

| After | Before | |

|---|---|---|

| Software | No | Warehouse Management System |

| Customer Communication | Email, phone | Integrated messaging system |

| Accounting | ERP without web interface. Inability to view inventory online. | Unified CTMS interface for real-time inventory and supply chain management. |

| Repair Confirmation | Confirmation via email. | Repair module with photos and notes, price negotiation through a special interface. |

| Storage Time Accounting | Manual counting of storage days. | Automated calculations with consideration of free storage days. |

| Receiving/Dispatch | Using Excel | Excel integration for managing statuses and train formations. |

| Reporting | Excel | EDI and API for data exchange with major shipping lines, automatic report generation. |

| Customer Service | Email communication. | Customer portal with detailed container status and request tracking. |

Why Choose Our CTMS?

Our Container Terminal Management System (CTMS) revolutionizes logistics operations by providing unprecedented efficiency, visibility, and control over your container movements. With features like real-time tracking and automated billing, we help you save time and reduce operational costs.

Features at a Glance

- Real-time container tracking

- Automated billing and invoicing

- Comprehensive reporting tools

- Intuitive customer portal

What Our Clients Say

“The implementation of this CTMS has been a game-changer for our operations. The efficiency we’ve gained has allowed us to serve our customers better and grow our business.” – [“Shenzhen Smart Logistics.]

Ready to Transform Your Terminal Operations?

Contact us today to schedule a demo and see how our CTMS can benefit your operations.

Personnel training and implementation at the enterprise.