| Multi-language | Action history | Maintenance repair: Visual damage editor service, Acceptance/refusal of repair |

| Invoices: Enhances financial operations with automated invoicing, charge calculation, and transaction management. | ERP Integration: Enables real-time data sync with ERP systems, improving accuracy across container inventory, financials, and operations. Eliminates redundant data entry, enhancing data integrity. | Fines Reduction: Automates workflows, cuts manual errors, optimizes resource use, and reduces labor costs. |

| Documentation: Digitizes & centralizes operational documents, streamlining access, reducing paperwork, and ensuring regulatory compliance. | Container Allocation: Provides tools for effective management of equipment and labor, maximizing utilization and minimizing downtime. | Data Integration & Connectivity: Offers seamless integration with external platforms & IoT devices, enriching supply chain visibility & data exchange. |

| Reporting & Business Intelligence:Generates in-depth reports and analytics for operational insights, facilitating informed decision-making and strategic planning. | Performance Monitoring & KPI Tracking:Tracks key performance indicators in real-time, aiding in performance improvement and target achievement. | Workflow Collaboration:Promotes effective communication and coordination among |

|

PUSH

|

MESSENGER

|

24/7

|

The cloud-based depot management system transforms inland depot operations into a comprehensive logistics platform. It integrates asset handling, resource planning, and container freight station operations, including preparing containers for shipment to the port and streamlining EDI communication with shipping lines. This all-in-one platform manages inventory, tracking, maintenance, billing, and reporting, fostering seamless collaboration across departments and with shipping lines and other external partners.

Features:

|

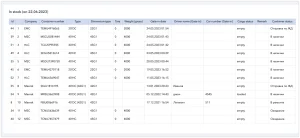

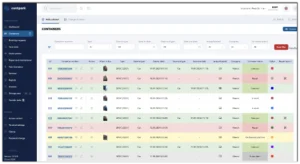

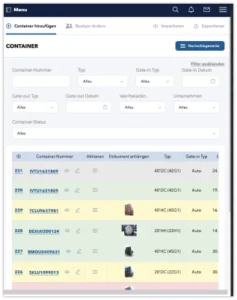

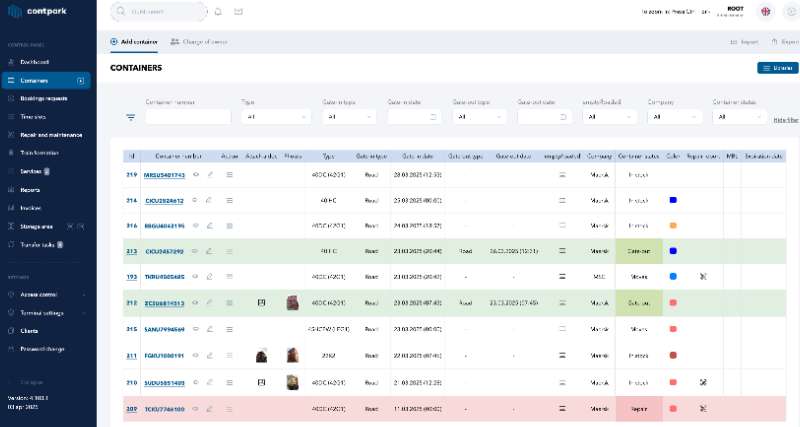

Inventory: Quick search for container details and change statuses in the registry, accounting for stocks with easy parameter filtering. Enables swift import and export via Excel for efficient depot container management |

|

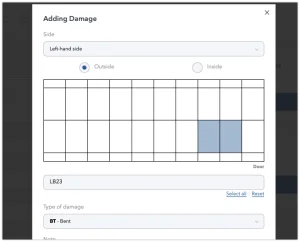

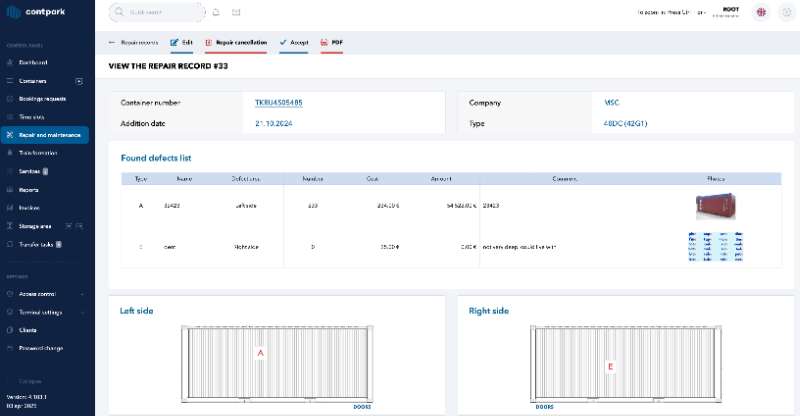

Maintenance and Repair: Accounting of the condition of containers received at the depot terminal. Personal cabinet for customers to accept repair estimates. |

|

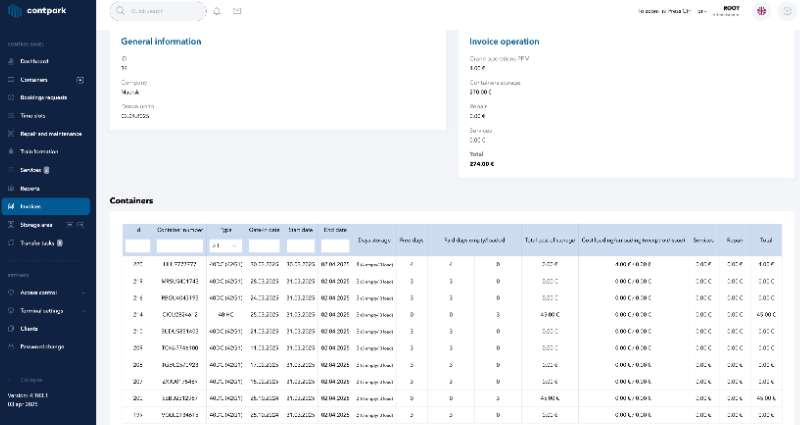

Billing and Invoicing: Overviews handling documentation and security checks, while automating invoicing and financial transactions for depot services |

|

Reporting & Analytics: Access real-time KPIs, operational, and financial data. Use EDI for seamless exchanges with shipping lines, streamline bookings, and swiftly create invoices. This precise approach enhances decision-making and strategic planning in container depot management. |

|

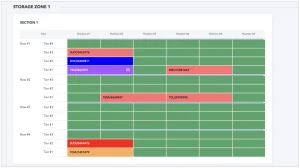

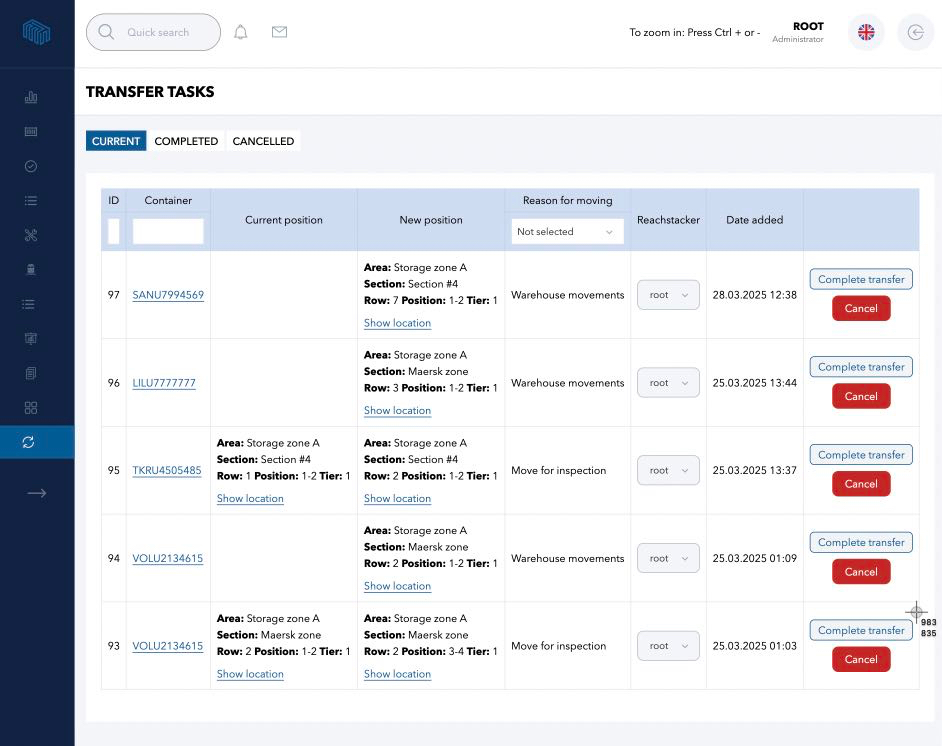

Tasking Cranes & Reachstackers: Implements advanced planning tools, including a non-GPS location system. Crane operators access coordinates on mobile devices, optimizing material handling and resource use at the depot and across the yard, ensuring efficient management of containers. |

|

Yard Management: Enhances container stacking, designs storage areas, integrates road transport logistics. Optimizes space utilization, ensuring efficient movement of containers and road vehicles within the depot. |

|

Mobile Application: The Contpark mobile app gives depot operators real-time access to key operations, enabling efficient management of containers, tasks, and yard activities. Operators and staff can quickly view container locations, assign tasks, and track maintenance through their mobile devices. This streamlined access optimizes workflow, improves communication, and enhances productivity across the depot. |

Security, Integration, and Customization Modules

Contpark Container Depot Management System includes advanced modules that enhance security, ensure compliance, and provide powerful customization tools.

With these features, depots can automate EDI exchanges, safeguard sensitive data, operate within certified private cloud infrastructure,

and generate detailed custom reports for better decision-making.

EDI Builder (CODECO/COARRI)

Configure, test, and automate EDIFACT workflows.

Ensures seamless communication with shipping lines, rail operators, and customs systems. |

Data Encryption (AES-256-CBC)

Protects sensitive data both in storage and during transfer.

AES-256-CBC ensures compliance with modern security standards. |

Private Cloud Security (ISO 27001)

Hosted on a private cloud environment certified under ISO 27001.

Guarantees controlled access, resilience, and full data ownership. |

Report Builder (Charts & Sheets)

Create custom tables, KPIs, and XY charts instantly.

Export reports in XLS or PDF formats for strategic decision-making. |

Interface:

Other features

Q&A

A software to automate and centralize depot operations, handling inventory, maintenance, billing, and reporting.

- Depot Efficiency: Automates tasks and reduces paperwork.

- Inventory Control: Offers real-time stock visibility.

- Container Tracking: Provides efficient real-time tracking.

- Maintenance Management: Simplifies scheduling and tracking.

- Financial Accuracy: Ensures precise billing.

- Data Insights: Delivers performance analytics.

It speeds up container handling, reduces wait times, and offers accurate tracking, enhancing overall service quality.

Yes, it integrates with logistics and supply chain systems for streamlined information exchange.

Yes, customization can tailor workflows, reports, and features to a depot’s unique needs and processes.

Examples of integration

| TYPE | Container depot. Reception / delivery: AUTO |

| Storage capacity | 300-700 TEU |

| Warehouse | Empty, loaded, tank |

| Services | Storing empty, laden, filling, unloading |

| Region | New Zealand |

| Departments | Reception/dispatch, fixing team, accounting, storage / warehousing |

| Improved | Previous | |

|---|---|---|

| Yard Optimization | Real-time space allocation | Manual space assignment |

| Gate movements | Automated processing system | Manual check-ins and check-outs |

| Inventory | Real-time monitoring | Periodic manual inventory |

| Damage Inspection | Digital submission with images | Manual forms submission |

| Operational Reporting | Instant analytics dashboards | Weekly manual reports |

| Customer Interface | 24/7 online portal access | Limited office hours service |

Maximize Efficiency

Discover the next level with our DMS, designed to streamline every aspect of your operations. From automated gate operations to sophisticated inventory management, our solution is built to increase productivity and reduce turnaround times.

Benefits

- Automated gates for efficient container in/out

- Dynamic yard for optimal space utilization

- Advanced damage inspection tools for accurate assessments

- Robust reporting and analytics for informed decision-making

Transform with us

Embrace innovation and let our Depot Management System transform your operations. Reach out to learn more about our technology and how it can tailor-fit your needs.