Overview

Contpark is a system that combines the capabilities of a Warehouse Management System (WMS) with the specialized tracking and organization functions of container yards and equipment. This system increases efficiency by automating operations with improved logistics, providing tools and solutions to manage your yard effectively.

Reachstacker tasks

- Simplify operations, minimize congestion, and optimize resource use for increased productivity. Reachstackers and other handling equipment manage pick-ups and drop-offs of containers efficiently, using global positioning systems for precise location tracking within the terminal, ensuring safe moves and helping to avoid delays.

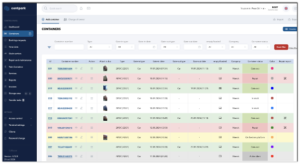

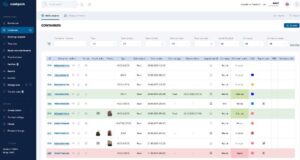

Quick search

- Offers real-time tracking and live status and availability of containers, ensuring inventory accuracy. Users can find any data they need quickly, preventing container misplacement and boosting efficiency and service quality.

Container Tracking Systems

- Facilitate quick container searches, streamline inventory and space utilization in your yard, and eliminate bottlenecks for faster handling and greater productivity. 2D visualized maps allow you to consider capacity constraints and optimize space.

Advanced Modules for Yard Security and Customization

The Contpark Container Yard Management System expands core yard operations with integrated EDI automation, enterprise-level encryption, ISO-certified cloud infrastructure,

and a flexible reporting engine. These modules bring stronger compliance, streamlined communication with partners, and actionable data insights for daily operations.

EDI Builder (CODECO/COARRI)

Automate EDIFACT flows for Gate-in/Gate-out events.

Ensures fast, error-free communication with shipping lines, rail operators, and customs directly from the yard. |

Data Encryption (AES-256-CBC)

Protects all container movement records, billing data, and user actions.

AES-256-CBC keeps yard operations secure and compliant. |

Private Cloud Security (ISO 27001)

Hosted on ISO-27001 certified private cloud.

Provides data resilience, controlled access, and complete ownership of yard information. |

Report Builder (Charts & Sheets)

Generate detailed yard KPIs, container turnover tables, and XY charts.

Export results in XLS/PDF to support planning and client reporting. |

Integration with CTMS

Deep integration with other systems, including Shipping and Vehicle Bookings modules, optimizing infrastructure utilization and creating a single container tracking platform. Seamless integration with other software modules ensures a complete workflow. YMS implementation increases real-time productivity and reduces costs.

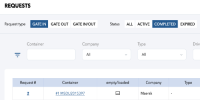

Customer portal

The customer portal now integrates accounting software, invoicing software, and supports order fulfillment processes, enabling comprehensive monitoring of container operations such as gate-in and gate-out from the warehouse and your yard, and more. Users can also efficiently manage and view accounting documents, simplifying the financial aspects of order processing directly through the portal.

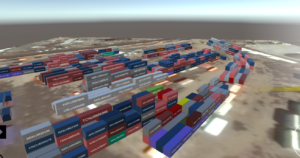

SaaS logistics

Our system provides real-time visibility and easy identification of containers, improving movement in yards and space allocation to reduce congestion. It integrates over the cloud with terminal operating systems, including Rail Management and Shipping modules, providing end-to-end visibility of container movement and improving efficiency. SaaS (cloud-based) is an efficient warehouse management solution that includes real-time tracking, cloud integration, and optimization algorithms that are automatically updated. It is scalable, provides performance analytics, and is suitable for terminals of any size, including Dry ports, improving control and decision-making.

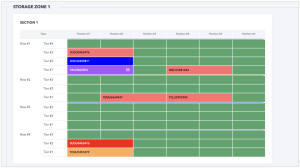

Yard Planning and Management

Terminal design editor with 2D visualized stack modeling and container search functionality. Consider capacity constraints and avoid congestion with easy-to-use tools.

The system eliminates routine paperwork, providing unprecedented efficiency and accuracy in container handling and load management. It is based on flexible site tools, allowing real-time tracking of containers and optimizing space on the sites. With the integration of reachstacker operations and other handling equipment, it enhances the storage and transport capabilities within your yard. This approach to operational planning ensures a seamless flow of containers, avoiding delays and improving overall logistics performance.

From warehouse logistics to dynamic task accounting, it’s a comprehensive method aimed at enhancing operational efficiency and inventory management. Simplifying the process of planning container placement, the software tools provide an eagle-eye view of your operations, including live status and availability of containers, ensuring that all transaction history is preserved. These easy-to-use tools facilitate effective space utilization, while tracking and real-time data analysis capabilities ensure precise monitoring and management of assets and tasks within the yard. Users can find any data they need quickly, improving workflow.

Interfaces with TOS/TMS/CTMS/CDMS systems, including Rail Management and Vessel scheduling modules, and is a beacon of integration, enabling data transfer between different modules of the system and ensuring a complete workflow.

The digital platform, designed for supply chain optimization, leverages cloud-based management and intermodal capabilities to enhance logistics and operational efficiency. It integrates inventory control, freight management systems, and Vehicle Bookings, facilitating seamless coordination across yard depot and railway container terminal operations. By employing advanced analytics, the platform provides insightful data to streamline processes, avoid delays, and improve decision-making.

The module focuses on gate scheduling and tracking, designed to enhance operational efficiency by ensuring accurate and real-time tracking of container movements, including pick-ups and drop-offs of containers. Key features include gate efficiency for streamlined transport scheduling, Vehicle Bookings to reduce wait times, and visibility enhancement for improved container tracking. The system leverages advanced tracking technology, such as global positioning systems, for precise movement analysis, optimizing logistics and transport management, and ensuring safe moves.

Leveraging EDI and API integration, mobile application functionality, and data analytics, we enhance yard management efficiency. This cross-platform approach boosts visibility and facilitates digital transformation, seamlessly connecting RFID technology, global positioning systems, and modern digital tools.

Customizable features for different container yard types, including Dry ports, and scalability to meet growing business requirements.

Ensures safety and compliance with industry standards, helping to avoid risks, and how its reporting tools help make decisions and improve processes.

The system integrates container inspection, damage assessment, repair scheduling, customer monitoring for repair, and repair cost estimates to enhance container maintenance efficiency. It identifies damages, considers repair urgency, schedules necessary repairs, tracks customer repair progress, and provides cost estimates, optimizing lifespan and reducing downtime.

|

Freeware demo – 14 days |  |

Download presentation / brochure (PDF) |

FAQ

A Yard Management System (YMS) streamlines container movements within a terminal’s yard, boosting efficiency by up to 30%. It offers real-time tracking, optimizes yard layout, manages gate operations, monitors equipment, including reachstackers and other handling equipment, and generates reports. It provides live status and availability of containers, ensuring operations run smoothly.

Implementing a YMS improves gate throughput and yard space utilization. It reduces congestion, enhances container tracking accuracy, streamlines operations, and supports data-driven decisions, collectively boosting terminal productivity and capacity.

A YMS typically features real-time container tracking, yard planning, and optimization tools that enhance space utilization. Gate management functions reduce processing times, equipment tracking improves allocation efficiency, and advanced reporting and analytics boost operational insights. Integration capabilities with other systems, like CTMS and Vessel scheduling, further enhance terminal efficiency.

Using advanced algorithms, a CYMS increases space utilization, suggests optimal container stacking strategies that reduce handling distances, and cuts yard congestion, leading to smoother operations, safe moves, and significant cost savings.

Yes, YMS can integrate with various terminal systems, including the Terminal Operating System (TOS), Rail Management, and billing systems, improving data exchange and operational coordination by 20%, which streamlines processes and enhances productivity across the board.

A YMS revolutionizes gate operations by automating check-ins and check-outs, managing Vehicle Bookings, cutting wait times, and boosting gate productivity. This leads to a smoother flow of trucks and containers, significantly enhancing operational efficiency.

With comprehensive reporting and analytics, a YMS provides insights to improve operational decision-making. It helps identify bottlenecks, track performance metrics, find any data, and analyze trends, leading to increased efficiency and productivity through optimized workflows.

A YMS enhances terminal productivity by optimizing container movements to reduce congestion, improve gate throughput, and enhance equipment utilization. It provides real-time visibility into operations, including live status and availability of containers, leading to increased handling efficiency for growing container volumes, making terminals more competitive and efficient.

ContPark: Streamline container terminal operations with our advanced Yard Management System. Maximize efficiency, reduce congestion, and optimize yard space utilization in your yard. Gain real-time visibility, including live status and availability of containers, automate processes, and improve overall productivity. Experience seamless integration with tools and solutions like Rail Management and Vessel scheduling, and make data-driven decisions. Unlock the potential of your container terminal.