Interface

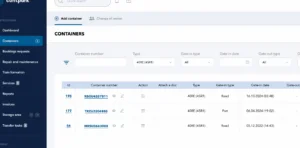

Detailed overview of container statuses and actions for efficient tracking and management.

Detailed overview of container statuses and actions for efficient tracking and management.

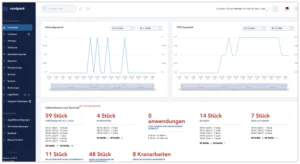

Visual display of key metrics, container activity, and TEU trends, offering real-time insights into terminal performance and efficiency.

Visual display of key metrics, container activity, and TEU trends, offering real-time insights into terminal performance and efficiency.

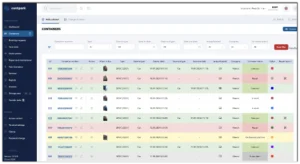

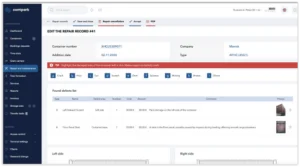

Detailed defect list with costs and photos. Clients can accept or refuse repairs in their personal account.

Detailed defect list with costs and photos. Clients can accept or refuse repairs in their personal account.

Key features

Gate-in / Out

- Automated identification of arriving and departing reefers

- Integration with gate management systems

- Recognition of container numbers for tracking and processing

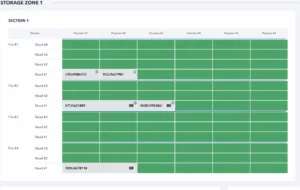

Yard Management

- Address-based storage of containers in the yard

- Formation of dedicated zones for specific cargo types

- Tracking container locations and movements across the terminal

Real-time Temperature Tracking

- Continuous monitoring of reefer container temperature

- Instant alerts on temperature fluctuations

- Remote control of cooling settings

Automated Alerts

- Notifications for temperature deviations

- Power failure and energy consumption warnings

- Customizable alert settings via mobile & desktop

System Synchronization

- Optional integration with TOS and ERP platforms

- Support for EDI-based automated data exchange

- Custom API synchronization for external systems

Remote Reefer Control

- Adjust temperature settings remotely

- Perform remote diagnostics of reefer units

- Cloud-based architecture enables customer access to temperature data

Reporting & Analytics

- Generate detailed temperature reports

- Track reefer performance over time

- Automatically send reports via email and EDI to clients

Optimization

- Recording and tracking reefer container parameters

- Monitoring energy consumption for operational insights

- Ensuring compliance with temperature storage regulations

All OS Support

- Compatible with Windows, Linux, and macOS

- Mobile support for Android and iOS

- Cloud-based access from any device

Introductory Case Information

The Reefer Monitoring System transformed reefer container operations by eliminating manual checks, reducing energy consumption, and enabling real-time tracking. With automated monitoring, predictive maintenance, and seamless system integration, the terminal achieved greater efficiency, cost savings, and improved cargo safety.

Reefer Monitoring System Implementation – Before & After Optimization

| Before Implementation | After Implementation |

|---|---|

| Manual temperature checks leading to delays and human errors | Real-time automated temperature tracking with instant alerts |

| No centralized reefer monitoring system | Integrated system with remote access and control |

| High energy consumption without optimization | Energy usage tracking and efficiency reports |

| Limited visibility on reefer performance and conditions | Data-driven insights and analytics for proactive decision-making |

| Reactive maintenance after breakdowns | Predictive maintenance alerts to prevent failures |

| No integration with other logistics or ERP systems | Seamless integration with EDI, API, and TOS |

| Time-consuming manual reporting | Automated reports in DOC/XLS/PDF formats |

Reefer Monitoring System – Feature Comparison

| Basic | Standard | Premium | |

|---|---|---|---|

| Core Features | |||

| Container inventory tracking (empty, loaded, reefer) | ✔ | ✔ | ✔ |

| Real-time temperature tracking | ✖ | ✔ | ✔ |

| Automated alerts for temperature deviations | ✖ | ✔ | ✔ |

| API integration (TOS, ERP, EDI) | ✖ | ✔ (Basic API) | ✔ (Full API & EDI) |

| Additional Features | |||

| Trial period | ✔ (7 days) | ✔ (14 days) | ✔ (30 days) |