Introduction to Terminal Operations

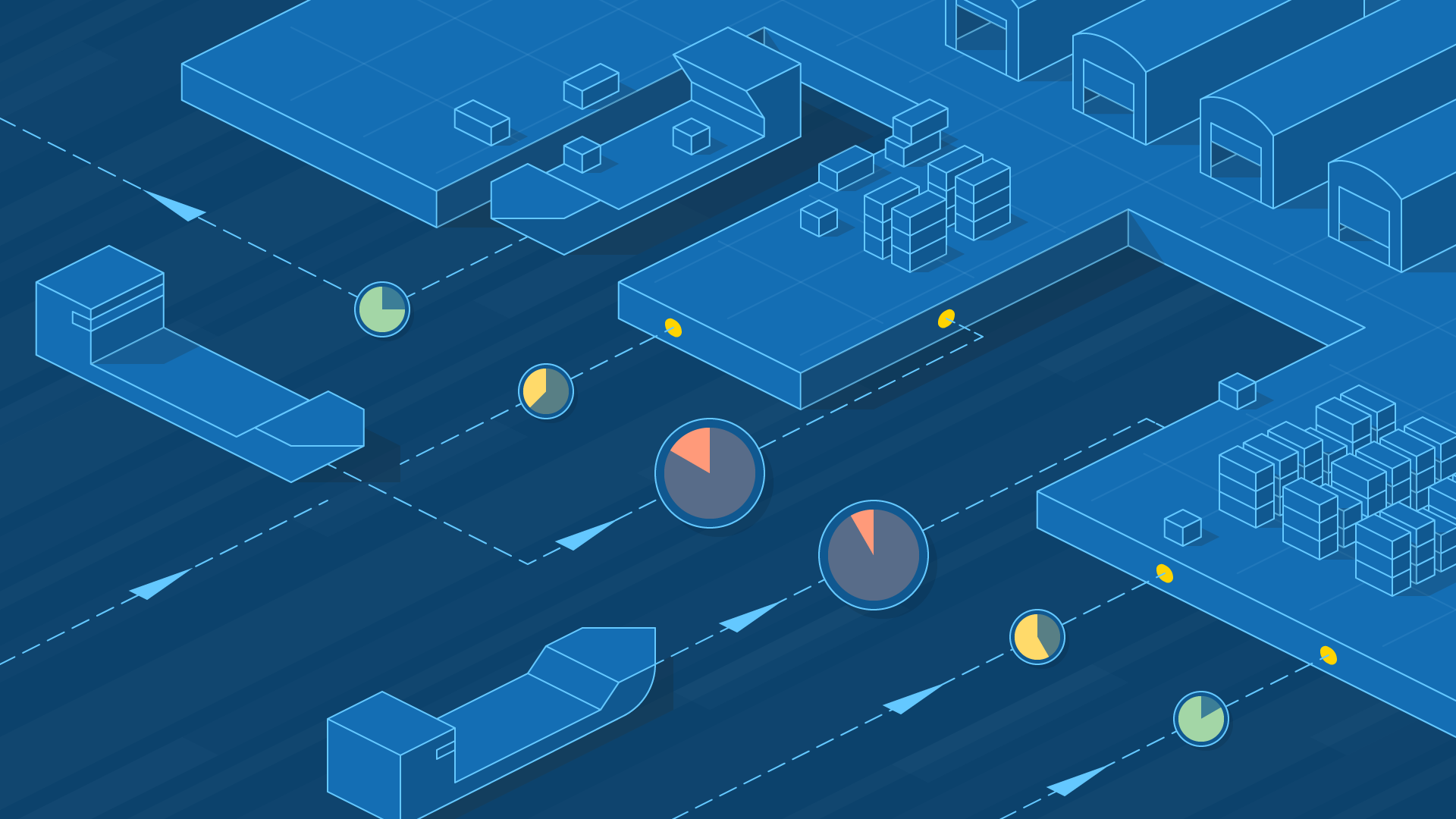

In the world of container logistics, the efficiency of terminal operations is paramount. Terminal Management stands at the core of operations efficiency, ensuring that port operations run smoothly and effectively. The role of terminals, pivotal in managing the flow of cargo and containers, has evolved with advancements in technology and changes in global trade patterns.

Efficiency in terminal operations directly influences the speed and reliability of cargo handling, affecting the entire supply chain. Through strategic terminal management, ports can optimize their operations, reduce turnaround times, and enhance overall service quality. This not only benefits logistic companies but also contributes to global trade efficiency.

Real-time System Technologies

The adoption of System Integration and Real-time Tracking technologies has revolutionized the logistics industry. RFID Technology, in particular, has provided an unprecedented level of visibility into the whereabouts and status of goods. These technologies enable real-time terminal operating systems to monitor container movements accurately, ensuring that every piece of cargo is accounted for.

Integrating these systems within the logistics infrastructure improves operational efficiency and minimizes delays. The ability to track cargo in real-time also enhances security and reduces the risk of loss or theft. Consequently, the implementation of these technologies is becoming a standard practice in modern terminal operations.

Container and Cargo Management

Container Management and Cargo Handling are critical aspects of logistics, directly impacting the speed and efficiency of the supply chain. The management of containers involves not just the physical handling of cargo but also the accuracy of inventory records. Inventory Accuracy is crucial for planning and forecasting, helping logistics operators to minimize storage costs and optimize the use of available space.

Efficient cargo handling and container management practices ensure that goods are delivered in a timely manner, reducing the likelihood of demurrage and detention charges. This efficiency is vital for maintaining customer satisfaction and competitiveness in the fast-paced world of international trade.

Enhancing Logistics Through Automation

Logistics Automation represents a significant leap forward in how shipping coordination and equipment allocation are managed. Automation in logistics not only speeds up processes but also reduces the potential for human error, leading to more reliable and efficient operations.

Shipping Coordination through automated systems allows for more precise planning and execution of shipping schedules, ensuring that resources are used optimally. Equipment Allocation becomes more dynamic and responsive to real-time demands, enhancing the overall efficiency of terminal operations.

By incorporating automation, the logistics sector can achieve higher levels of operational efficiency, cost-effectiveness, and service quality. This not only benefits logistics providers but also the entire global supply chain.

| Feature | Manual Processes | Automated Systems |

|---|---|---|

| Tracking Accuracy | Low | High |

| Operational Speed | Moderate to Slow | Fast |

| Cost Efficiency | Less Efficient | Highly Efficient |

| Error Rate | Higher | Lower |

| Scalability | Limited | Excellent |