A recent assessment conducted by the Royal Bank of Canada (RBC) has brought attention to the current global shipping network’s critical condition, characterized by increasing port congestion. This issue has led to significant backlogs of container ships and longer turnaround times at major ports worldwide.

To address this challenge, CNBC has developed an innovative solution called Supply Chain Heat Maps, providing interactive visualizations of port efficiency. As an illustration, the Port of Oakland in the United States is experiencing substantial difficulties, with vessels facing an average unloading and loading time of 6 days, and imported containers enduring an average wait of eleven days for transportation. Similar issues are observed at the ports of Los Angeles and New York.

Various factors contribute to the slowdown and bottlenecks, including COVID-19-related lockdowns in China, geopolitical tensions, rising fuel prices, inadequate terminal facilities, and operational inefficiencies. While terminal managers have limited control over global issues, they can optimize their operations and leverage technology to improve workflows and reduce processing time.

This article emphasizes the significance of terminal operating software, exploring its key functionalities, integration possibilities, and its potential to enhance port productivity. It is important to note that the discussion focuses exclusively on cargo terminals and does not encompass other port activities such as fishing, ferries, or cruises.

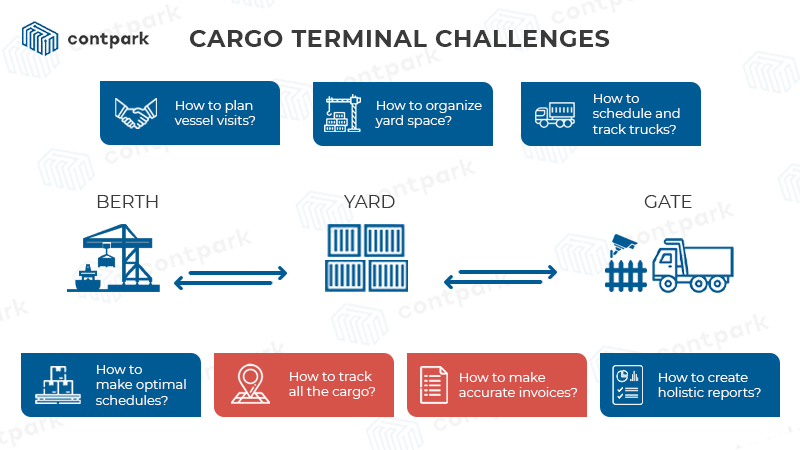

What are the main terminal operating problems?

Cargo terminals encompass a wide range of ports and facilities, each with its unique characteristics. While they differ in size, location, and freight types, their primary functions generally involve servicing vessels, handling freight, and facilitating inland transportation. Vessel-related activities include discharge, repairs, and refueling, while freight operations encompass loading/unloading, storage, and container operations. Additionally, cargo terminals play a crucial role in connecting cargo to the wider transportation network. Despite these differences, common pain points arise in key areas such as the berth, yard, and gate, necessitating efficient management and coordination to optimize terminal operations.

Disruptive vessel calls planning

Managing vessel operations involves navigating through various challenges, especially in terms of scheduling berth windows, coordinating loading and unloading equipment based on estimated time of arrivals (ETAs), and ensuring effective communication with shipping lines to facilitate smooth operations.

Successfully addressing these challenges requires meticulous arrangement of all the components like puzzle pieces, optimizing the sequence of loading and unloading activities, and maintaining open lines of communication with the carrier’s system to enhance operational efficiency. The complexity intensifies when faced with vessel delays and other disruptions, leading to wasted time, fuel, and port resources. As a result, operators must react swiftly and make necessary adjustments in berth and resource allocation. These tasks can be highly demanding without the assistance of specialized software designed for this purpose.

Inefficient yard space configuring

Efficient management of the terminal yard, which serves as a vast storage area, is essential for ensuring operational effectiveness. This involves addressing various complexities such as optimizing cargo allocation, coordinating handling equipment and staff, and organizing truck movements.

To streamline yard operations, it is necessary to establish different storage areas and allocate freight based on future operations. Given the significant volume of containers and diverse cargo types handled by terminals daily, attempting to manually manage these processes is impractical.

Therefore, the utilization of automated systems and software plays a pivotal role in yard management. These tools enable efficient allocation of cargo, facilitate coordination among handling equipment and staff, and assist in optimizing truck movements, thereby enhancing overall operational efficiency within the terminal.

Lengthy truck visits arrangement (appointment booking, permission granting, verification, etc.)

Gate management is a critical component of terminal operations, focusing on overseeing the movement of vehicles as they enter and exit the facility. The primary goal is to allow access exclusively to authorized vehicles while verifying cargo information at the gate. However, manually conducting these checks is not only time-consuming but also prone to errors.

Moreover, when a substantial number of trucks enter and leave the terminal for freight delivery or pickup, it can result in congestion and bottlenecks if the workflow is not properly organized. Therefore, establishing an efficient and well-structured flow is essential to ensure effective gate management.

To streamline gate operations, terminals rely on automated systems and advanced technology. These tools enable the quick and accurate verification of authorized vehicles and cargo details. Additionally, they facilitate smooth traffic flow by implementing optimized routing and scheduling, reducing waiting times and mitigating potential congestion. By embracing such solutions, terminals can enhance gate management efficiency, strengthen security measures, and boost overall operational productivity.

Complicated staff and equipment scheduling

Efficient scheduling presents substantial hurdles, especially in large-scale enterprises with diverse operational divisions. The seamless coordination of staff and equipment schedules within a terminal relies heavily on the punctuality of vessel and truck arrivals and departures. However, integrating these complex elements can prove challenging, particularly when unexpected circumstances such as equipment malfunctions or delays disrupt the planned schedule. Such disruptions can quickly escalate the situation, leading to a chaotic environment.

Inefficient cargo tracking resulting in lost freight

Effectively monitoring the flow of cargo within a terminal is a prevalent and critical challenge that directly impacts operational efficiency and profitability. The seamless tracking of goods throughout their entire journey, from arrival to unloading/loading, transshipment, and storage, is paramount to prevent any potential losses within the dynamic and bustling terminal environment.

Inaccurate billing that leads to lost revenue

Terminals handle a significant number of billable operations each day for multiple customers. Ensuring the precise recording and inclusion of these charges in invoices can be a challenging task when done manually. The manual process often burdens operators with extensive paperwork, despite their dedicated efforts, leading to a higher risk of mistakes being introduced into the system.

Data leakages in reporting and analytics activities

Terminal operators rely on comprehensive visibility into their facility’s activities to ensure efficient operations. Monitoring key performance indicators (KPIs) across various categories is crucial, including gate events, truck movements, inventory, vessel operations, equipment productivity, yard utilization, and demurrage/detention. Generating informative reports requires data collection from different departments, but traditional organizational structures often hinder seamless data sharing, leading to information leaks and communication delays. To overcome these challenges and enable holistic data analysis, an integrated system is essential.

In the digital age, technology plays a pivotal role in optimizing terminal operations. Contemporary software solutions offer advanced capabilities to enhance performance and competitiveness. Let’s explore how these modern technologies can revolutionize terminal management.

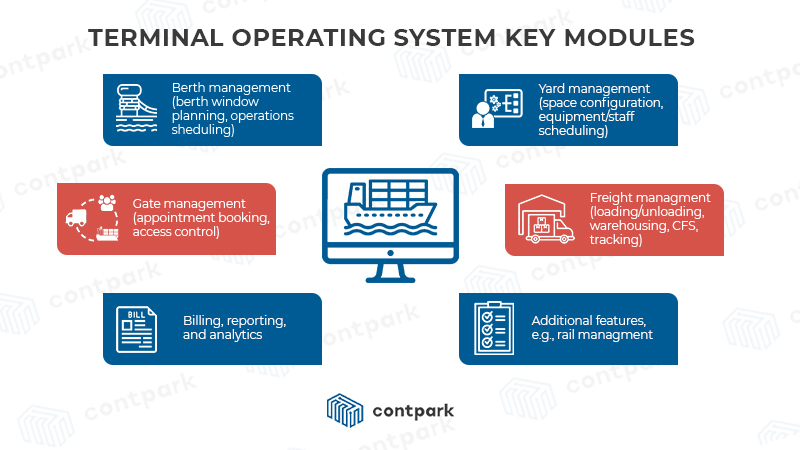

The terminal operating system and its key modules

The interconnected core modules of a terminal operating system (TOS) work in synergy to deliver a comprehensive range of functionalities. These modules are developed to optimize operations and enhance productivity within cargo terminals and ports. By integrating various components, the TOS enables seamless coordination between different logistical elements, including vessels, trucks, cranes, trains, and port personnel. This integration facilitates real-time tracking of cargo movements, efficient allocation of resources, and data-driven analysis for informed decision-making. Through the interconnected core modules, the TOS empowers terminals to enhance operational productivity, streamline processes, and provide exceptional service to stakeholders.

Berth management: planning vessel visits and predicting ETA

In the maritime industry, the smooth management of berths and vessel movements is essential for efficient operations. Electronic Data Interchange (EDI) technology has traditionally been used for information exchange, including berth management. Carriers or agents transmit the BERMAN (berth management) message to the port, containing vital details about the vessel, berth requirements, expected operations, and mooring requests. The integration of a Terminal Operating System (TOS) is paramount to ensure the effective reception and processing of this information.With the TOS in place, terminal operators can seamlessly synchronize ship-related activities. They can efficiently schedule vessel visits, manage movements between terminals (if required), coordinate associated services, and organize the deployment of tugboats and personnel. For terminals operating in areas with significant tidal variations, a TOS equipped with dynamic tidal modeling capabilities is indispensable for the safe and optimized management of vessel movements.

To enhance accuracy in estimated time of arrival (ETA) predictions, terminals often leverage their own data sources in addition to information provided by shipping lines. An increasingly common practice is to integrate with the Automatic Identification System (AIS), which enables real-time vessel tracking. By leveraging AIS data, terminals can make more precise ETA estimations, allowing for effective planning and resource allocation. This integration empowers terminals to optimize their operations based on reliable and up-to-date information.

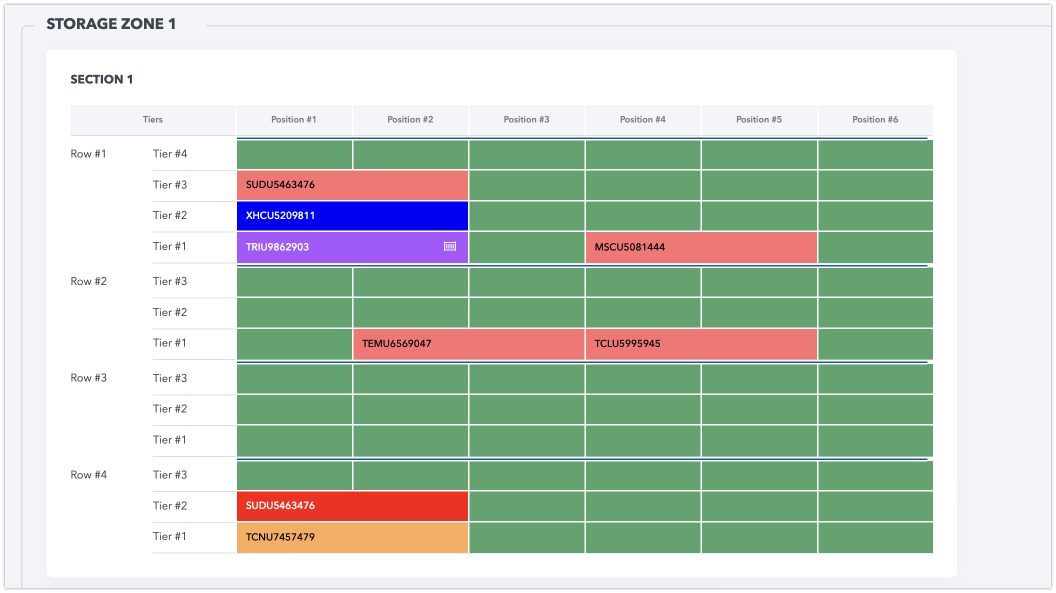

Yard management: arranging cargo movement and allocating terminal resources

Yard management involves the efficient management of cargo, equipment, vehicles, and personnel within the yard is crucial for the smooth operation of warehouses, terminals, and distribution centers. The Terminal Operating System (TOS) plays a pivotal role in automating and optimizing yard management processes, as discussed earlier. The TOS facilitates a range of yard management tasks, including:

- Defining designated areas for different cargo types and operations, such as loading, unloading, storage, and transshipment, ensuring organized and efficient workflow.

- Allocating, scheduling staff and equipment, such as Automated Rail-Mounted Gantry (ARMG) cranes, Automated Stacking Cranes (ASC), forklifts, based on operational requirements and optimizing resource utilization.

- Utilizing a Real-Time Locating System (RTLS) to track the real-time location of equipment, enabling accurate monitoring and efficient deployment.

As a centralized repository of information, the TOS stores comprehensive data on incoming and outgoing freight, allowing for effective coordination of equipment, personnel, yard space. The TOS’s load planning functionality assists in configuring yard areas and arranging cargo in the most efficient manner, maximizing space utilization and considering load constraints for subsequent operations.

Additionally, having a real-time view of yard processes empowers terminal operators to promptly address any disruptions or challenges, ensuring smooth operations and timely resolution.

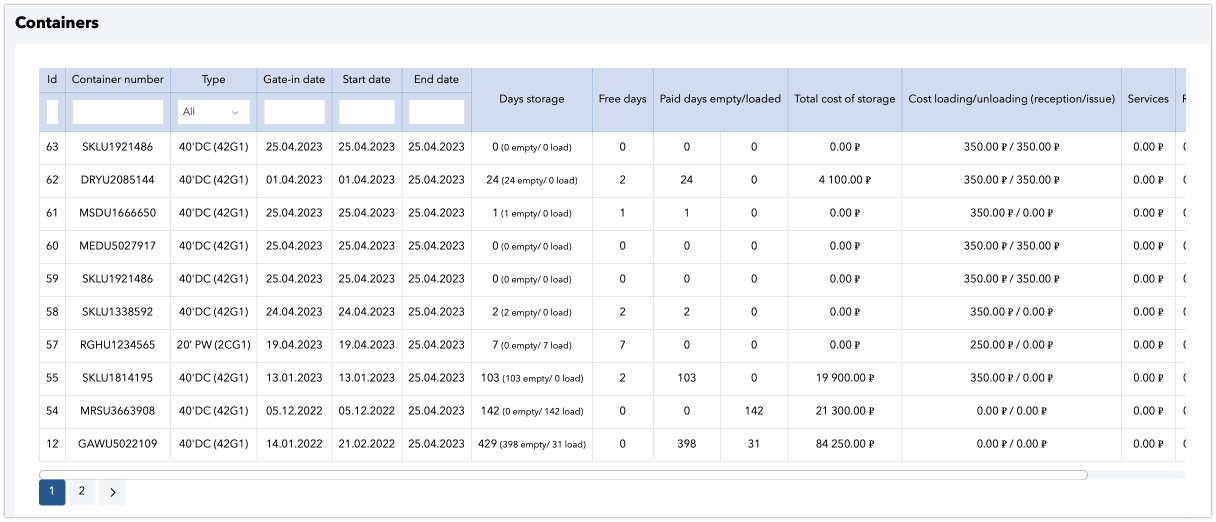

Freight management: cargo tracking, storage, and other services

A Terminal Operating System (TOS) serves as a comprehensive repository for managing the vast array of cargo that flows using the terminal infrastructure. It is imperative for the TOS to possess the flexibility and versatility required to handle the diverse range of cargo types encountered, including containers of different sizes, Roll-On/Roll-Off (RORO) cargo, general cargo comprising dry and break bulk with varying packaging, liquid bulk, logs. Additionally, the TOS must be capable of effectively managing specialized cargo such as IMDG hazardous materials, goods with temperature sensitivity, and oversized or irregularly shaped freight.

To improve the efficiency in terminals, mathematical models and heuristic for berth allocation can play a significant role, particularly when considering berth scheduling updates and simulated annealing techniques for optimization. Operational research is applied to examine models and solution methods that address complex terminal processes, such as ship berthing and the quay crane operations. This includes mathematical models aimed at the supply chain efficiency, supporting part logistics with modes transportation that integrate planning the berth allocation.

A lot of terminals provide warehousing capabilities and offer additional services like warehousing and container transshipment operations. The TOS plays a pivotal role in facilitating the efficient allocation of storage space and closely monitoring the movement of cargo within terminal. To enhance visibility and tracking, RFID technology is commonly employed, utilizing tags affixed to cargo items that are automatically identified and tracked, with the pertinent information seamlessly transmitted to the TOS database. For a more in-depth exploration of tracking technologies, refer to papadimitriou the dynamic studies the systems used.

Furthermore, certain ports extend their services to include ancillary cargo-related operations such as stuffing and unstuffing, freight consolidation or deconsolidation, and container rentals. The TOS seamlessly manages all of these diverse operations, encompassing order reception, execution, and accurate billing, thereby ensuring streamlined and effective handling of these services while upholding exemplary operational standards produced for country editors of vessels. Hybrid solutions continue to emerge, enabling ports to meet evolving demands in a dynamic cargo environment.

Gate management: controlling access to terminal facility

The gate management module within a Terminal Operating System (TOS) plays a critical role in the efficient coordination and monitoring of vehicle movements at the terminal, ensuring safety across all processes. It encompasses various features and functionalities that contribute to the smooth operation of the gate, supporting careers in logistics and technology and berth allocation planning.

One of the primary functions of the gate management module is vehicle booking. This feature enables carriers to schedule appointments and register important details, such as vehicle information, driver information, freight specifics, supporting both cargo and cars. By having this information in advance, the verification process during arrival becomes streamlined and expedited, contributing to an efficient supply chain and addressing the berth allocation problem with multiple restrictions.

To ensure compliance with security standards, the gate management system is designed to adhere to the International Ship and Port Facility Security Code (ISPS). This code outlines the necessary security measures that ports must follow to safeguard their operations in the world of global logistics, affecting the container port productivity and capacity around America.

The automation of gate operations involves integrating multiple components and technologies. These include self-service driver kiosks, optical character recognition (OCR) cameras, radio frequency identification (RFID) scanners, intercom devices, automated security barriers, and information displays, making it easy for single drivers to navigate the terminal.

Self-service driver kiosks provide a user-friendly interface for drivers to complete the necessary verification processes, eliminating the need for paper-based procedures. OCR cameras are used to capture and register important vehicle information, such as license plates and container details. RFID scanners help with cargo identification and efficient inventory management. Automated security barriers play a vital role in regulating vehicle access at the gate, allowing entry only to authorized vehicles and enhancing terminal security. Intercom devices serve as communication tools, enabling seamless and efficient interactions between drivers and terminal staff, promoting quick assistance and effective information exchange. Additionally, information displays serve as valuable resources, providing drivers with clear instructions and pertinent information, contributing to improved operational efficiency within the company.

Seamless data exchange is crucial for the effectiveness of these gate management technologies. Integration with other modules within the TOS allows for the smooth sharing of data related to vessels, containers, vehicles, traffic, supporting berth planning and the assignment problem for various types of cargo. This data can be further utilized for traffic analysis, operational insights, and informed decision-making. All rights reserved.

Financial and reporting modules: supporting billing and analytics

Undoubtedly, the behind-the-scenes managerial activities play a pivotal role in the smooth functioning of terminal operations. One such essential component is the integration of a multi-currency billing module into the Terminal Operating System (TOS). This module empowers terminal managers to efficiently document and track all billable terminal operations, providing a comprehensive and accurate record, similar to proceedings in a university setting. With its capabilities to generate precise invoices, manage revenue streams, handle dynamic tariffs and rates, and accommodate stochastic variables in financial data, the billing module becomes a vital tool in financial control and formulation of strategies for revenue optimization.

Furthermore, the TOS offers the advantage of customizable reports and robust data-driven analytics for better understanding of financial flows. These features provide terminal managers and their team with a holistic view of facility performance, enabling them to make informed and strategic decisions that save on costs. The ability to download and export reports in various standard formats, such as XML, CSV, PDF, etc., ensures seamless sharing of information with stakeholders, including trailers used for logistics insights. Additionally, the TOS platforms prioritize security by offering different access levels, safeguarding the integrity and confidentiality of data.

Additional feature: rail management

When it comes to terminals that form part of an intermodal supply chain and encompass an adjacent rail facility, the integration of rail management functionality becomes a critical aspect. This functionality is intricately woven into the Terminal Operating System (TOS), allowing for the seamless planning of train loading and discharge sequences, efficient allocation of resources, and smooth execution of diverse rail-related operations.

TOS integrations

In the earlier discussion, we emphasized the significance of uninterrupted data exchange in a complex terminal system. Now, let’s delve into the essential integrations that play a vital role in optimizing terminal performance within a Terminal Operating System (TOS). However, prior to exploring these integrations, it is important to gain insights into the diverse approaches and methodologies employed for their successful implementation.

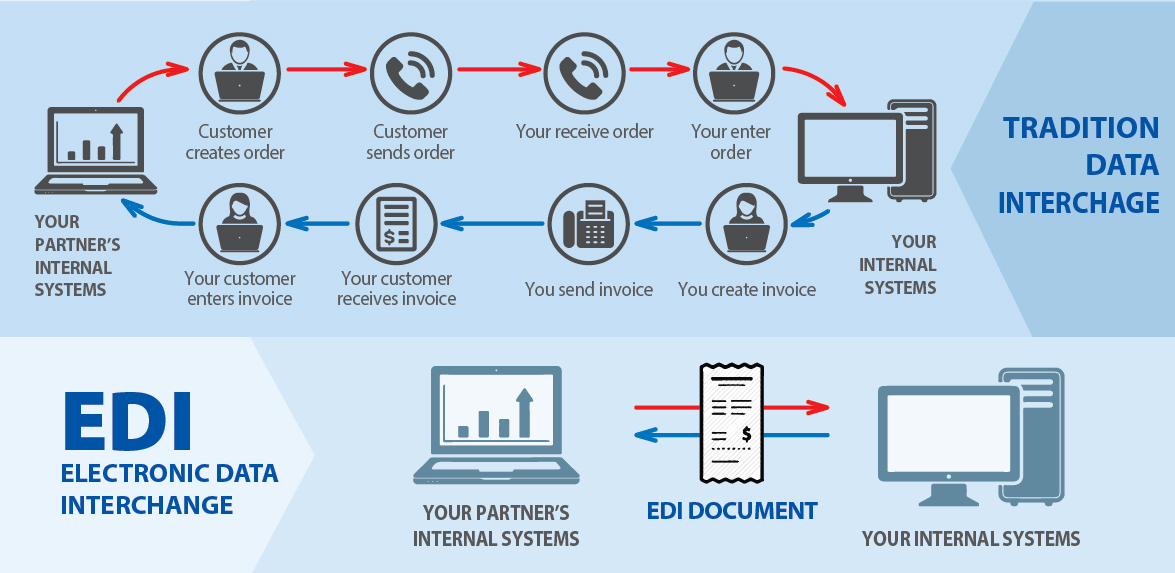

EDI vs API

As mentioned earlier, the maritime industry has traditionally relied on Electronic Data Interchange (EDI) technology for exchanging cargo-related information among ports, shipping lines, and other stakeholders. EDI enables direct data transfer between systems, replacing slower and less efficient methods such as paper-based processes, phone calls, or emails.

The two primary EDI standards used in the industry are UN EDIFACT (common outside the US) and ANSI (common in US). EDI facilitates the exchange of critical documents, including bills of lading, customs manifests, loading/discharge orders and confirmations, stowage instructions, vessel plans, and more. The integration of EDI message processing functionality has become a standard feature in modern Terminal Operating Systems (TOSs), enabling automated document sharing.

However, as the EDI format has been in use for decades, major carriers like Maersk, CMA CGM, and MSC are adopting newer integration methods, particularly APIs (Application Programming Interfaces) and the JSON (JavaScript Object Notation) messaging format. This shift towards APIs and JSON allows for more streamlined and efficient data sharing.

In the maritime industry, a rising data sharing platform gaining popularity is TradeLens, which provides a set of REST APIs for integration purposes. TradeLens utilizes blockchain technology to ensure data security and aims to enhance collaboration across global supply chains. For example, carriers can share information such as vessel position, estimated time of arrival (ETA), electronic bills of lading, and detailed cargo data. This enables terminals to plan their operations effectively, while shippers, brokers, and consignees can easily track their shipments.

In addition to facilitating external integrations, APIs are increasingly being used to connect internal systems within organizations operating in the maritime industry.

Internal integrations: GOS, RTLS, reefer monitoring, and others

Terminal operators employ diverse approaches to connecting internal software systems, as each terminal has its distinct operational characteristics and technology ecosystem. Nevertheless, there are numerous avenues for integrating these systems, often involving the establishment of an Internet of Things (IoT) infrastructure that incorporates a range of sensors, smart devices, and interconnected software for efficient data processing. Consider the following examples:

Gate Operating System (GOS): Seamlessly integrating your standalone GOS, including sensors, cameras, and RFID scanners, with your Terminal Operating System (TOS) empowers land carriers to access information about incoming vessels and register their vehicles and cargo. Simultaneously, you can acquire comprehensive data about vehicle flow, enabling enhanced operational oversight.

Real-Time Locating System (RTLS): To ensure effective tracking of terminal handling equipment, technologies like GPS, DGPS, RFID, and Bluetooth can be utilized. An RTLS entails the use of tags or wireless transponders affixed to equipment units, along with strategically positioned readers in various terminal zones to receive tag signals and determine their precise locations.

Reefer Monitoring System: For terminals handling refrigerated or frozen cargo, integrating a reefer monitoring system into the TOS provides convenient access to critical information regarding temperature-sensitive freight. This facilitates efficient management of cold chain logistics and helps ensure cargo integrity.

Radio/Mobile Data Terminals (RDT/MDT): Wireless networks employing diverse technologies are established within terminals to connect field workers with control operators. Handheld, stationary, or vehicle-mounted devices equipped with RDT/MDT functionality enable terminal personnel to receive instructions from the TOS and facilitate seamless communication.

Financial, Business Intelligence, and General Ledger Systems: Many terminals leverage dedicated business management solutions such as SAP, Microsoft Business Central, or Oracle’s Enterprise Resource Planning (ERP) system to handle back-office operations encompassing accounting, analytics, reporting, sales, marketing, and more. Establishing robust connectivity between these systems and the TOS is crucial for seamless information exchange and comprehensive data integration.

It is important to note that these examples represent just a fraction of the possibilities, and the specific systems and technologies employed may vary depending on the unique requirements and characteristics of each terminal.

External integrations: shipping lines, freight brokers, tracking data providers

To ensure operational synchronization and effective information exchange, terminals commonly establish connections with shipping lines and freight brokers using technologies like EDI (Electronic Data Interchange) or more advanced platforms like TradeLens. These connections enable maritime carriers to notify ports about their visits and freight particulars, while shippers and brokers can book empty containers. Terminals can then confirm bookings, manage loading and unloading operations, and perform various other tasks.

Another vital external connection utilized by terminals is the AIS (Automatic Identification System) data feed mentioned earlier. This data feed provides up-to-date information regarding ship positions and other marine-related data. It plays a critical role in vessel and freight tracking, accurate estimation of arrival times (ETA), and efficient berth management. Well-established providers offering robust APIs for accessing AIS data include MarineTraffic, Vessel Finder, and AISHub.

Popular TOS providers

We don’t promote any of the TOS providers but want to give a brief overview of the most popular products on the market to give you an idea of existing options.

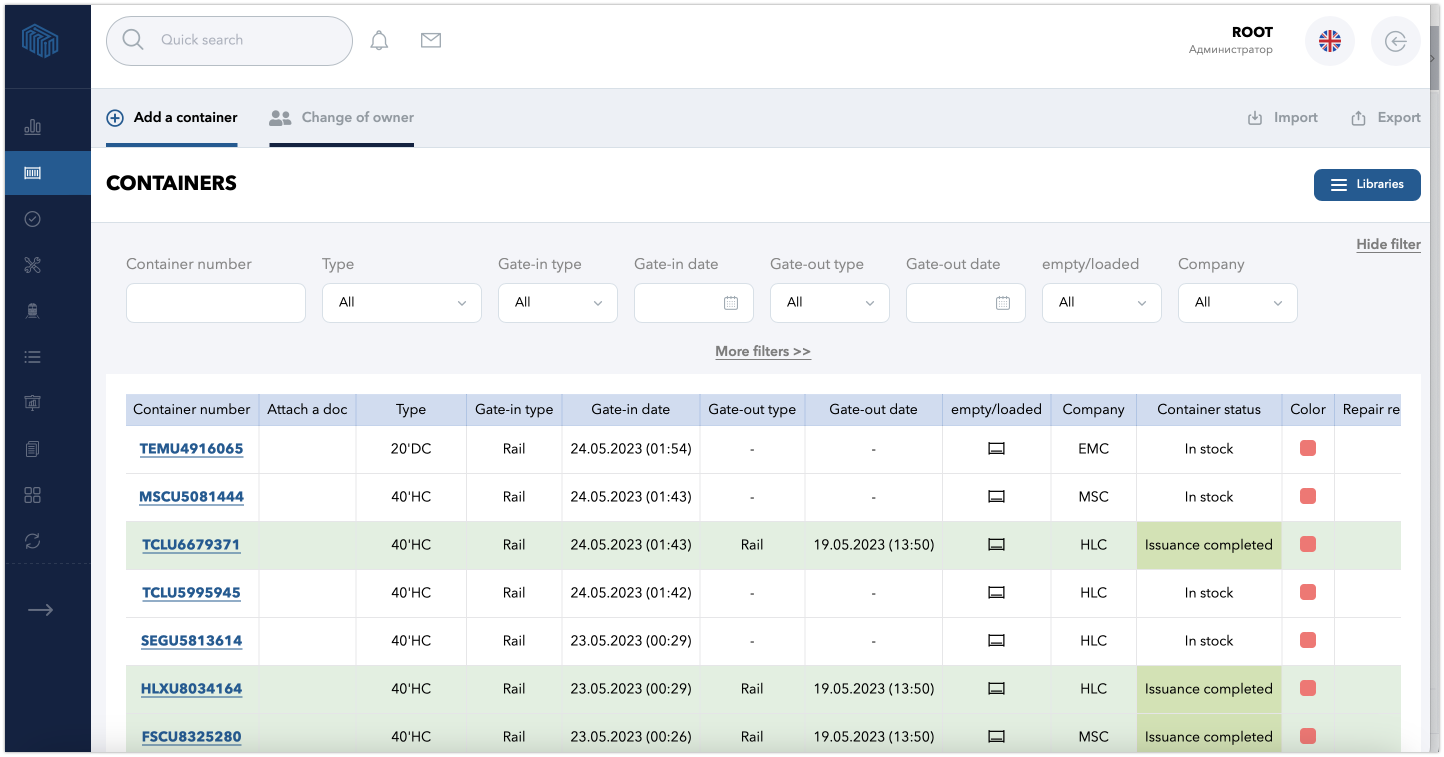

- ContPark: ContPark is an automated container terminal management system designed to optimize internal processes and assign tasks among service personnel. It facilitates customer interaction with dispatchers within a unified information space and handles container reception, discharge requests, and report generation. The software enables the accounting department to calculate service prices quickly, and clients can access dynamic stock statistics and container parameters.

- Navis: Navis offers a range of cloud-based supply chain execution and visibility technology solutions. Their products include yard management, transportation management, maintenance and repair operations, terminal operating systems, and ocean carrier and vessel solutions. Navis aims to address inefficiencies and data gaps in the global supply chain by consolidating software assets across key nodes and modes.

- CARGOES: CARGOES, developed by DP World, is a suite of next-generation logistics products leveraging machine learning and IoT technology. It caters to various global trade participants such as freight forwarders, customs agencies, importers, and exporters. CARGOES provides a portfolio of logistics services and products tailored to the specific needs of these stakeholders.

- CATOS: CATOS (Computer Automated Terminal Operating System) by Total Soft Bank Ltd. is an all-in-one, user-friendly solution for terminal operations. It consists of three modules: Planning, which helps schedule berth, yard, and vessel-related operations; Operation, which monitors and controls real-time operations; and Management, which supports billing, reporting, and analytics workflows.

- TBA Group: TBA Group specializes in automation solutions for ports, warehouses, and industrial plants. Their Autostore TOS is a management software designed for container terminals, while CommTrac TOS facilitates bulk and break bulk cargo operations. These platforms, available on-premises or in the cloud, offer features such as yard and asset management, vehicle booking systems, dynamic planning modules, and billing functionality.

- RBS: Realtime Business Solutions (RBS) develops software applications for the Container Handling Industry. Their TOPS Expert Enterprise is an on-premises platform, and TOPS Expert Cloud operates on a pay-as-you-go model. These solutions include management and optimization modules for various terminal operations, ranging from gate processes to billing. Optional modules can be added based on specific requirements.

Please note that these are just a few examples, and there are many other TOS providers available in the market, each offering unique features and functionalities to suit different business needs.

Buy, build, or modernize?

There are several options to consider when choosing a Terminal Operating System (TOS). Each option has its own advantages and considerations based on your specific needs and available resources.

When to build: If you require a highly customized solution that seamlessly integrates into your workflow, building a TOS from scratch may be the best option. However, keep in mind that developing a proprietary system of this magnitude can be a lengthy and costly project.

When to buy: If you find that existing TOS solutions on the market can meet your needs with minimal customization, purchasing an off-the-shelf solution may be the most efficient choice. However, some degree of fine-tuning and integration into your existing tech ecosystem will still be necessary.

When to modernize: If you already have a TOS in place but it is built on outdated technologies or lacks certain functionalities you require, a gradual modernization project may be suitable. This allows you to improve your system incrementally without disrupting ongoing operations.

In any approach you choose, consider leveraging modern technologies such as machine learning to enhance planning, analytics, and decision-making processes. While there may be associated costs, harnessing the power of data can provide a significant competitive advantage in today’s world.

Ultimately, the decision between buying, building, or modernizing a TOS should be based on a thorough assessment of your specific requirements, available resources, and long-term goals.