Definition

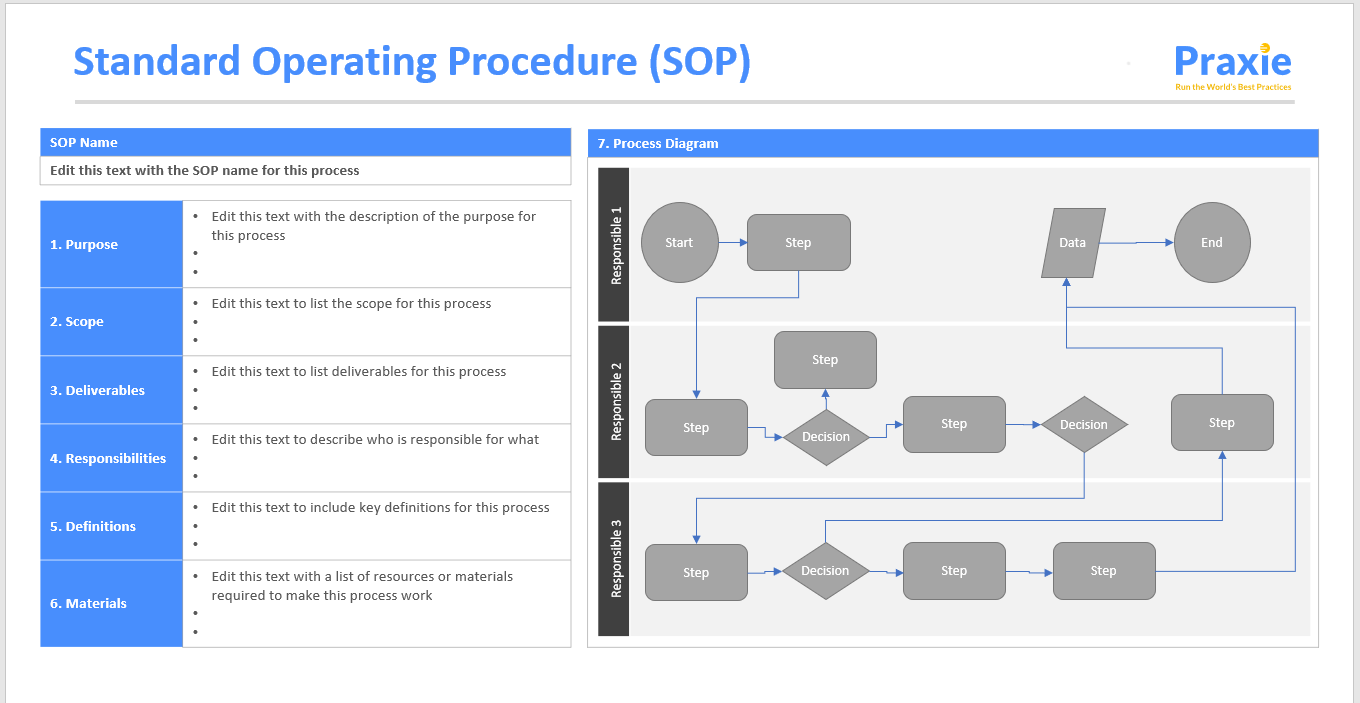

Standard Operating Procedures (SOP) are approved, written instructions that

describe how to perform a recurring operation in a consistent, controlled way. An SOP

documents the exact steps, roles, tools and safety rules required to complete a task so that

any trained employee can execute it with the same result.

Purpose

SOPs convert operational know-how into a formal process. They reduce dependence on

individual experience, support compliance with internal policies and external regulations,

and create a repeatable baseline for training, audits and continuous improvement.

Typical Structure of an SOP

- Title and ID: clear name, process owner and document code.

- Scope and objective: where the procedure applies and what result it must deliver.

- Roles and responsibilities: who does what at each step.

- Step-by-step procedure: ordered actions with checks, decision points and exceptions.

- Safety and compliance: PPE requirements, risk notes, legal or customer rules.

- Inputs and outputs: required data, forms, system records and expected result.

- References and records: links to forms, work instructions, KPIs and logbooks.

- Revision control: version, approval date and review cycle.

Use in Logistics, Yards and Terminals

In logistics operations and container terminals, SOPs are used to standardize critical flows

across gates, yard, warehouse and transport. Typical examples include:

- gate-in / gate-out processing for trucks, containers and trailers;

- yard location assignment, stacking rules and re-handling limits;

- reefer plug-in, temperature checks and alarm response;

- damage inspection, photo capture and survey reporting;

- documentation control for EIR, B/L, customs status and seals;

- exception handling for mis-shipments, mismatched units or hazardous cargo;

- incident reporting, near-miss registration and escalation.

In modern facilities SOPs are often embedded into a TOS, CTOS, WMS or YMS as on-screen

workflows, checklists and mandatory fields that guide dispatchers, clerks and equipment

operators step by step.

Business Benefits

-

Process stability: reduced variation in how tasks are executed across

shifts, sites and teams. -

Quality and service: fewer errors in documents, yard moves and shipments,

more predictable lead times for customers. -

Compliance and safety: visible proof that legal, customs, safety and

customer requirements are built into daily work. -

Training efficiency: faster onboarding of new staff using documented

procedures and checklists instead of informal shadowing only. -

Operational analytics: clear process baseline for measuring KPIs and

identifying bottlenecks for improvement.

Lifecycle and Governance

Effective SOP management includes assigning a process owner, keeping all procedures in a

controlled repository, and reviewing them on a fixed cycle or after major incidents, audits

or system changes. Updated SOPs must be communicated, trained and, where relevant, reflected

in digital workflows and forms.

In a mature logistics or terminal environment, SOPs, work instructions and system

configurations form a single process framework that supports safe, lean and scalable

operations across the entire network.

“`